MS Bond All Adhesive

Category:

Adhesive

Application:

Features:

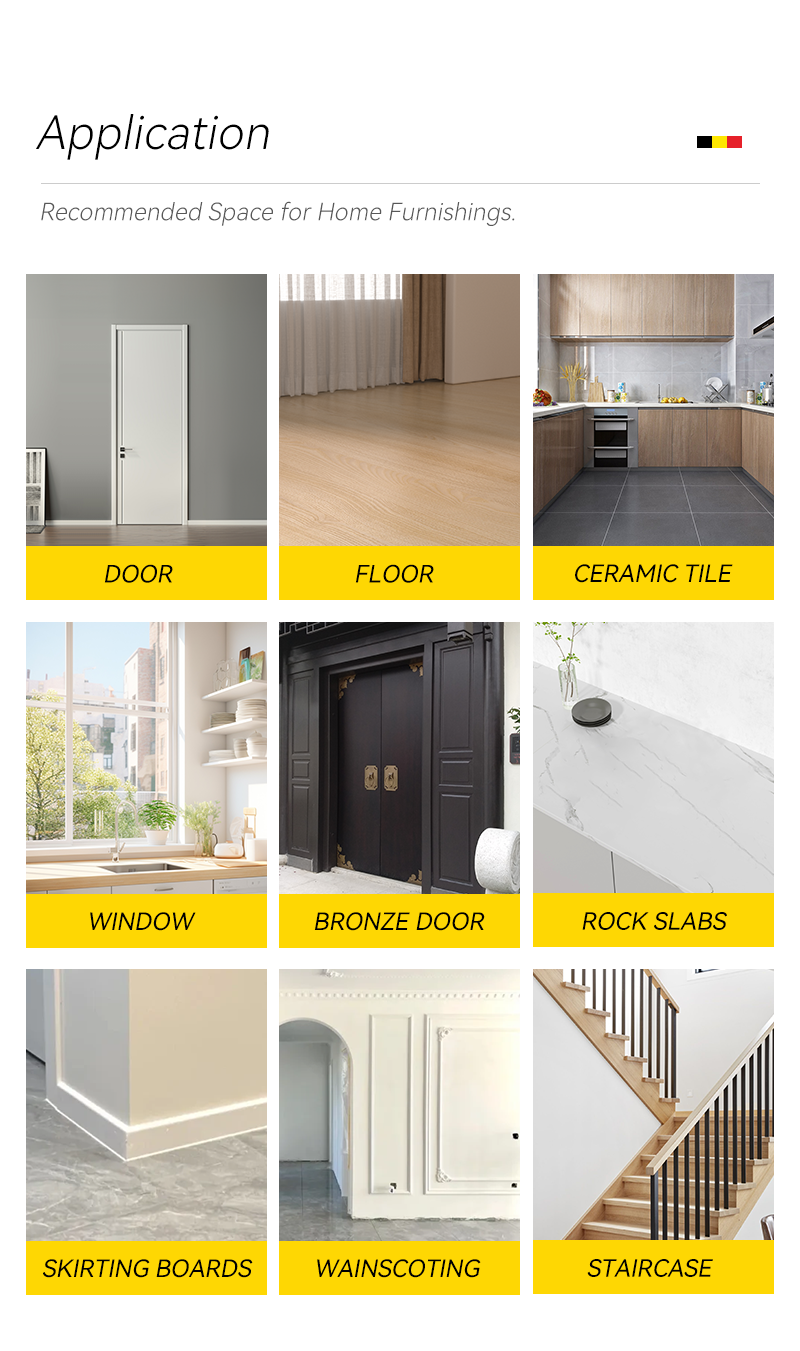

Suitable for bonding of basically all material surface, aluminium, aluminium & wood composites, ABS, steel, Zincalume, fiberglass, brick, colorbond, PVC flashing, concrete, ceramics, timber, MDF, plasterboard, polystyrene, glass, mirrors, tile, porcelain, etc. Also suitable for installation of different kind of materials big panels.

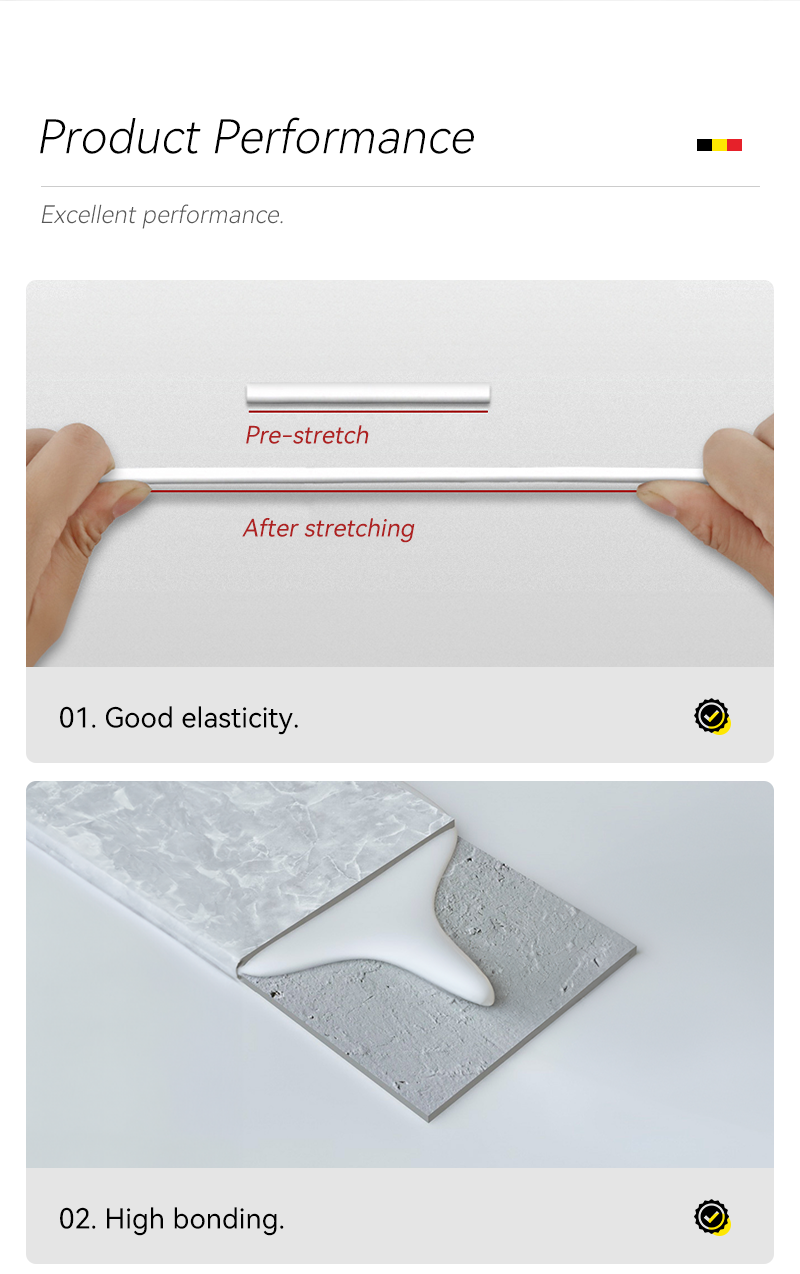

1. Grabs fast; 2. High impact resistance; 3. For almost all substrates; 4. Strong bonding performance

Product Profile:

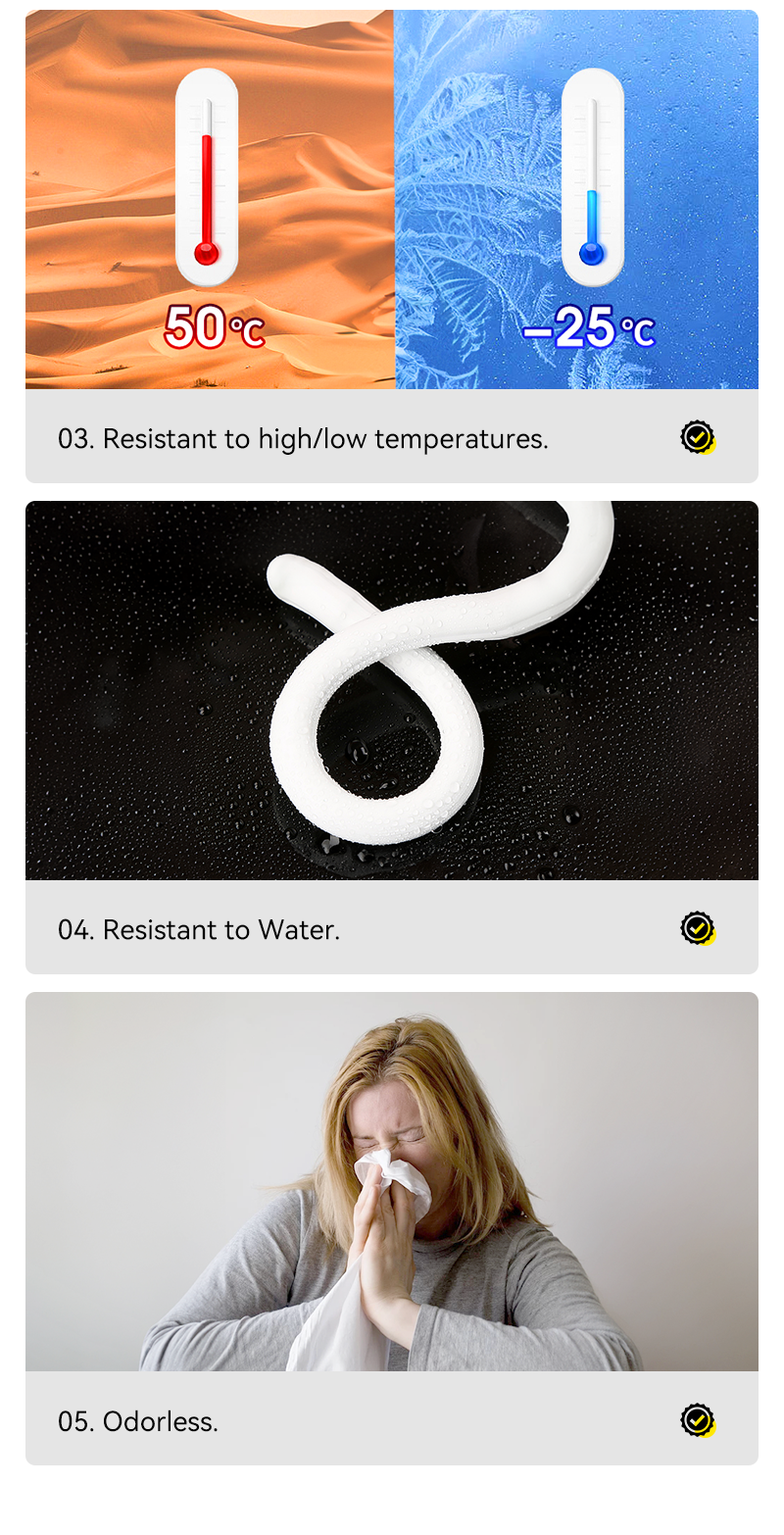

乐播传媒 Bond-All adhesive is mainly made of silane-modified polyurethane polymer, which also call MS polymer. This adhesive grabs almost all substrates fast with excellent bonding strength and high impact resistance.

Application:

Suitable for bonding of basically all material surface, aluminium, aluminium & wood composites, ABS, steel, Zincalume, fiberglass, brick, colorbond, PVC flashing, concrete, ceramics, timber, MDF, plasterboard, polystyrene, glass, mirrors, tile, porcelain, etc. Also suitable for installation of different kind of materials big panels.

Features:

1. Grabs fast; 2. High impact resistance; 3. For almost all substrates; 4. Strong bonding performance

MS Bond All Adhesive

Product Profile:

乐播传媒® MS Polymer Adhesive is a new type of environmentally friendly adhesive based on silane-modified polyurethane polymer. This technology originated in Japan and has been widely used in Japan, Europe, America and other markets. MS Adhesive has super strong adhesion and durable weather resistance, and is suitable for bonding and laying of rock slabs, large slabs, and ceramic tiles. At the same time, it is widely used in rock slab background wall (bonding of Oriented Strandboard and rock slab or metal pendant and rock slab); custom furniture and wardrobe installation in the whole house; installation of under-counter basin, etc.

Volume: 590ml/Set

Shelf life: 9 months

MOQ: 1000 Sets

Delivery time: 20 days

Loading Port: Zhongshan or Guangzhou

Technical Data Sheet

|

No. |

Test items |

Unit |

Testing Standard |

Test results |

Result |

|

1 |

Apperance |

—— |

Product should be a fine, uniform paste without air bubbles, crusts or gels |

Smooth Paste meet the requirements |

Pass |

|

2 |

consistency |

cm |

specified value 7.5 ± 1 |

7.5 |

Pass |

|

3 |

density |

g/cm3 |

specified value±0.1 |

1.64 |

Pass |

|

4 |

Surface curing time |

min |

≤60 |

20 |

Pass |

|

5 |

Sag |

mm |

≤3 |

0.5 |

Pass |

|

6 |

extrusion |

ml/min |

≥150 |

400 |

Pass |

|

7 |

Hardness |

HA |

30 - 90 |

50 |

Pass |

|

8 |

Anti-yellowing |

168H/△E |

≤ 6 |

< 2 |

Pass |

|

9 |

Bonding Strength |

MPa |

≥ 2 |

3 |

Pass |

|

10 |

Tensile modulus |

MPa |

HM: 23℃: >0.4 or -20℃:>0.6 |

23℃: 1.0; -20℃: 1.2 |

Pass |

|

11 |

Tensile adhesion |

—— |

no damage |

no damage |

Pass |

|

12 |

Tensile adhesion after flooding |

—— |

Soak in 23℃ water for 4 days, put it under standard test conditions for 1 day and then test: no damage |

no damage |

Pass |

|

13 |

Cohesion after cold drawing - hot pressing |

—— |

(Store at -20℃ for 3h, stretch for 21h: place at 70℃ for 3h, compress for 21h: after repeating one round, place for 3d under standard test conditions) is a cycle, after 2 cycles: no damage |

no damage |

Pass |

|

14 |

mass loss rate |

% |

≤8 |

1.3 |

Pass |

|

Remark |

The test results will change with the change of temperature and humidity |

||||

Prev

Next

Prev

Epoxy Adhesive

Next

More Products

Leave A Message